Food processing equipment with accessories / reaction kettle / tank cleaning nozzle / stainless steel welding / thread / GD series fixed cleaning ball

316L stainless steel cleaning ball / stainless steel fixed cleaning ball / spray ball / stainless steel fixed nozzle

GD series static CIP spray ball

| Model | CIP spray ball |

| Material | 304ss, 316Lss on request |

| Spray angle | 360° or on request |

| Connection type | thread, slip-on (tube clip), welding or clamp on request |

| Connection size | 1/8", 1/2", 3/4'', 1", 1 1/4", 1 1/2", 2" |

| Operating pressure | 1-3 bar |

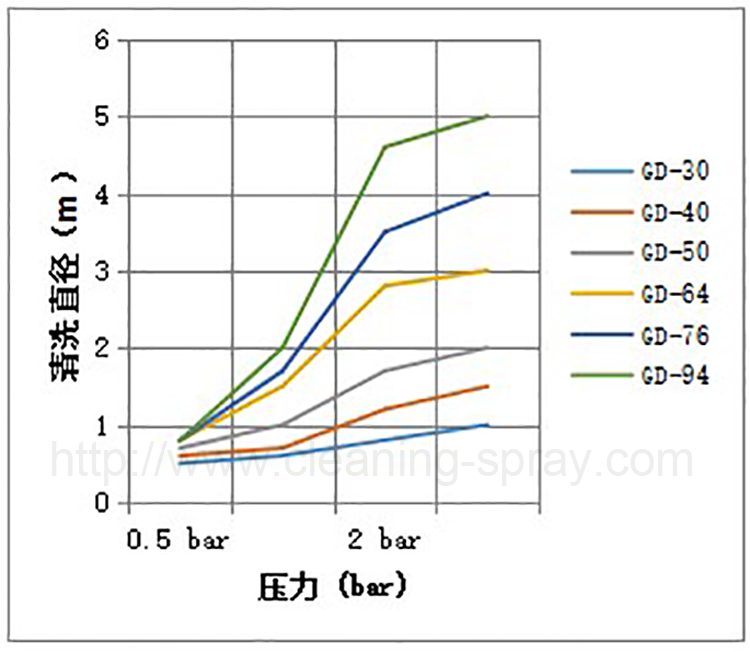

| Cleaning diameter | 1-3m |

GD series static CIP spray ball Design feature:

- Popular sprayball design

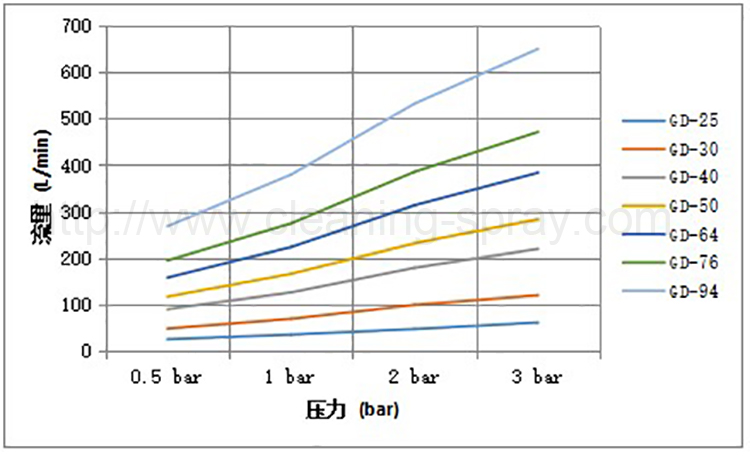

- For higher flow rate

- Corrosion resistant material

- Available in different sizes

GD series fixed cleaning ball works:

Fixed spray ball sprays a lot of water column through a large number of small holes to clean the inner wall of the tank

GD series fixed cleaning ball advantages:

Simple, basic maintenance-free, cost-effective, jet steam and compressed air, self-draining

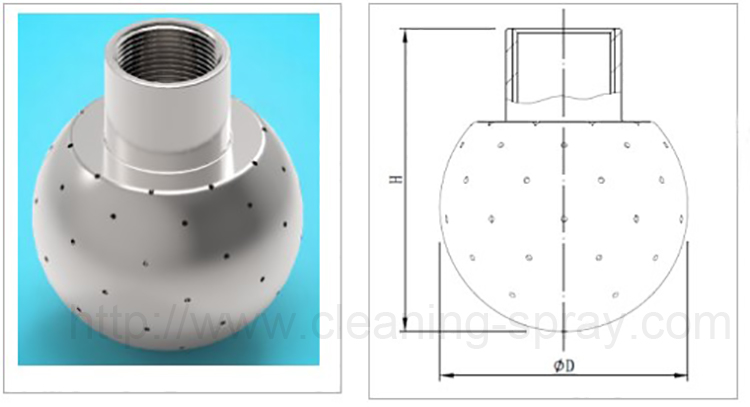

GD series fixed cleaning ball picture:

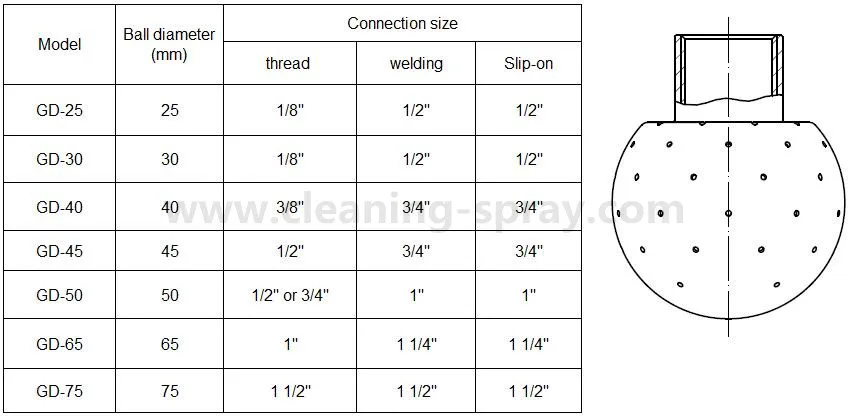

GD series fixed cleaning ball technical parameters:

●Structural structure

●Sharp solid jet

●Can be used for saturated steam injection

●Maximum cleaning diameter: 1-5 meters

●The highest temperature resistance is 200 degrees

●Material: 304, 316 stainless steel, 316L stainless steel, material optional

● Popular spherical design

● for large traffic (optional)

●Corrosion material (optional)

●Complete size and specifications

●Connection method: thread welding bolt, etc. can be customized

●The spray angle can be customized (mainly 360°)

Performance data:

Performance data:

Dimension:

GD series fixed cleaning ball application:

The GD Series is a fixed spray ball used in the food and beverage industry to clean tanks. Fixed spray balls are used for lower cleaning tasks. For high flow and steam injection.

Chinese

Chinese