cip rotary tank cleaning spray balls design features :

1. Double bearing design with excellent rotation effects, and better stability and longer life bearing

2. Self-cleaning self-lubricating design

3. Low consumption of liquid, operating at low pressure

4. 360 degree self-rotating cleaning nozzle, cleaning every place of your containers

5. The compact and hygienic design meets requirements for use in CIP system

6. Driven and lubricated by the cleaning fluid

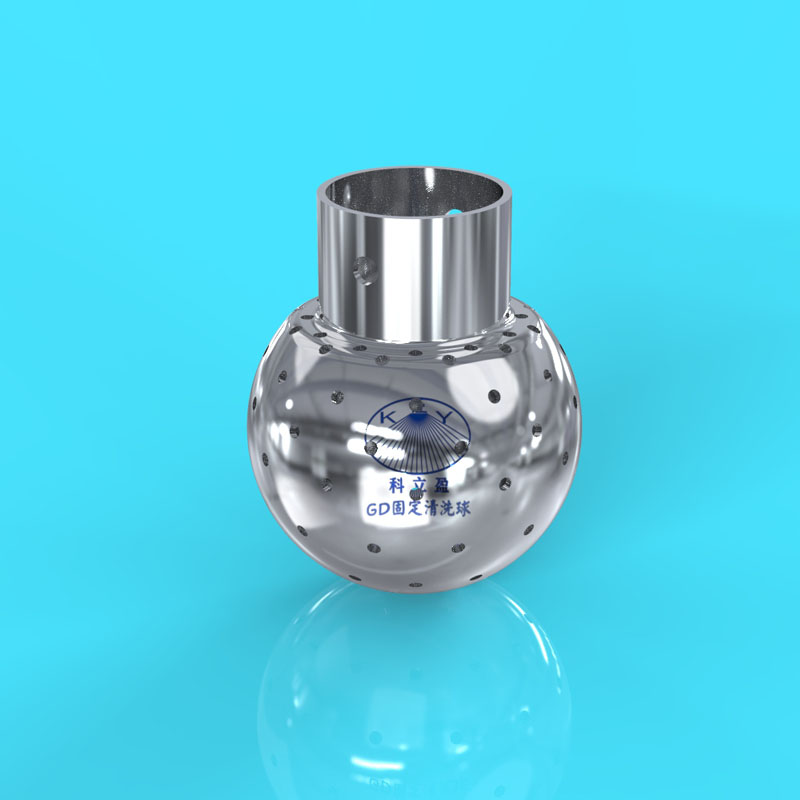

D50 316L SS cip rotary tank cleaning spray balls:

| Model: | D50 cip rotary spray balls |

| Material: | 316L ss |

| Connection: | 1-1/2" BSPP, 1-1/2" slip-on, 2" welding |

| Bearing: | double ball bearing |

| Pressure: | 2-4 bar |

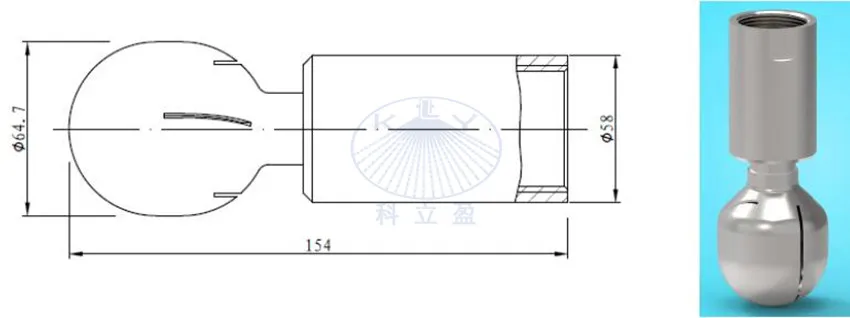

| Diameter: | 65mm |

| Spray diameter: | 4m |

| Temperature: | 130° |

| Installation: | Operation in every direction is possible |

| Filtration: | Line strainer with a mesh size of 50 Mesh |

| Application: |

rinsing and cleaning of tank or equipment |

cip rotary spray ball,360degree self-rotating tank cleaning spray balls common application:

- Soup kettles

- Batch processing vessels

- Yeast propagation tanks

- Ink and paint mixing vats

- Fluid bed dryers

- Brew kettles

- Storage tanks

- Spray dryers

- Commercial ovens

e.g: in food industry, beverage industry, pharmaceutical industry and chemical industry

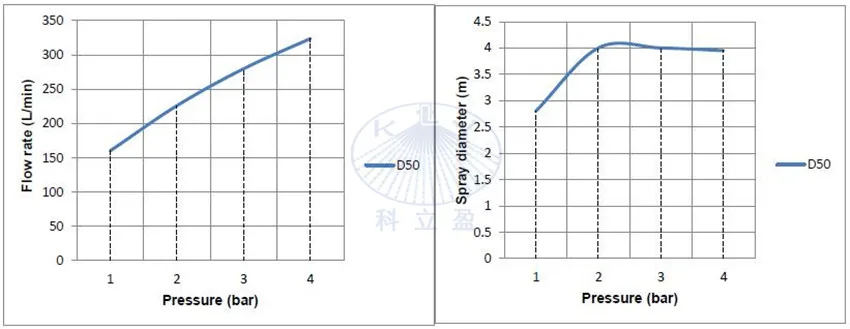

Tank cleaning spray balls performance parameter:

tank clean spary balls dimension:

Cip balls application:

D50 rotary spray heads tank cleaning spary balls are used to rinse and clean tank up to diameter 4m .,360degree self-rotating spray ball.

Chinese

Chinese